Singapore's trusted CNC precision engineering partner for 35+ years

Established Singapore-based precision engineering company delivering world-class CNC machining, turnkey assembly, and manufacturing solutions to aerospace, semiconductor, optics, medical, and industrial clients globally.

When precision matters most

Global manufacturers trust Shine Precision Engineering for high-mix, low-volume precision components when supply chains shift and reliability is critical. As a trusted contract manufacturer, we deliver complex CNC components that meet the world's most demanding quality standards. Discover the Singapore manufacturing advantage.

Manufacturing services

Your trusted partner for complex precision parts. We deliver uncompromising quality in every project.

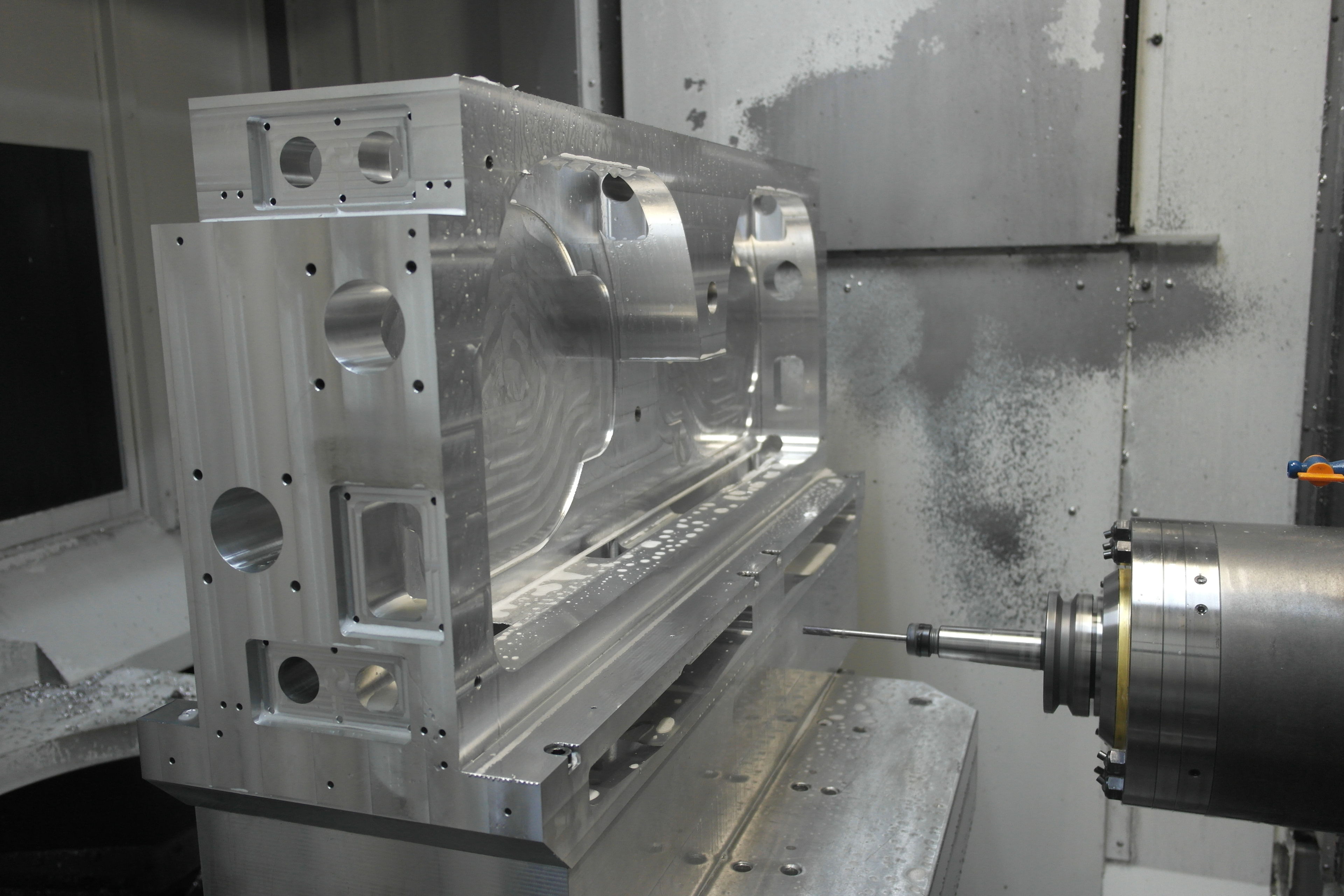

CNC milling

Transform designs into precise components with our advanced 3-, 4-, and 5-axis CNC milling technology.

Learn moreCNC turning

Achieve superior surface finishes with our expert CNC turning services.

Learn more

Surface finishing

Enhance performance and aesthetics with our comprehensive surface finishing options.

Learn more

Turnkey assembly

Complete solutions from concept to delivery with our turnkey assembly services.

Learn more

- 50+CNC Machines

- ISO9001:2015 Certified

- 10K+CNC parts made monthly

- 50+Metal & plastic materials

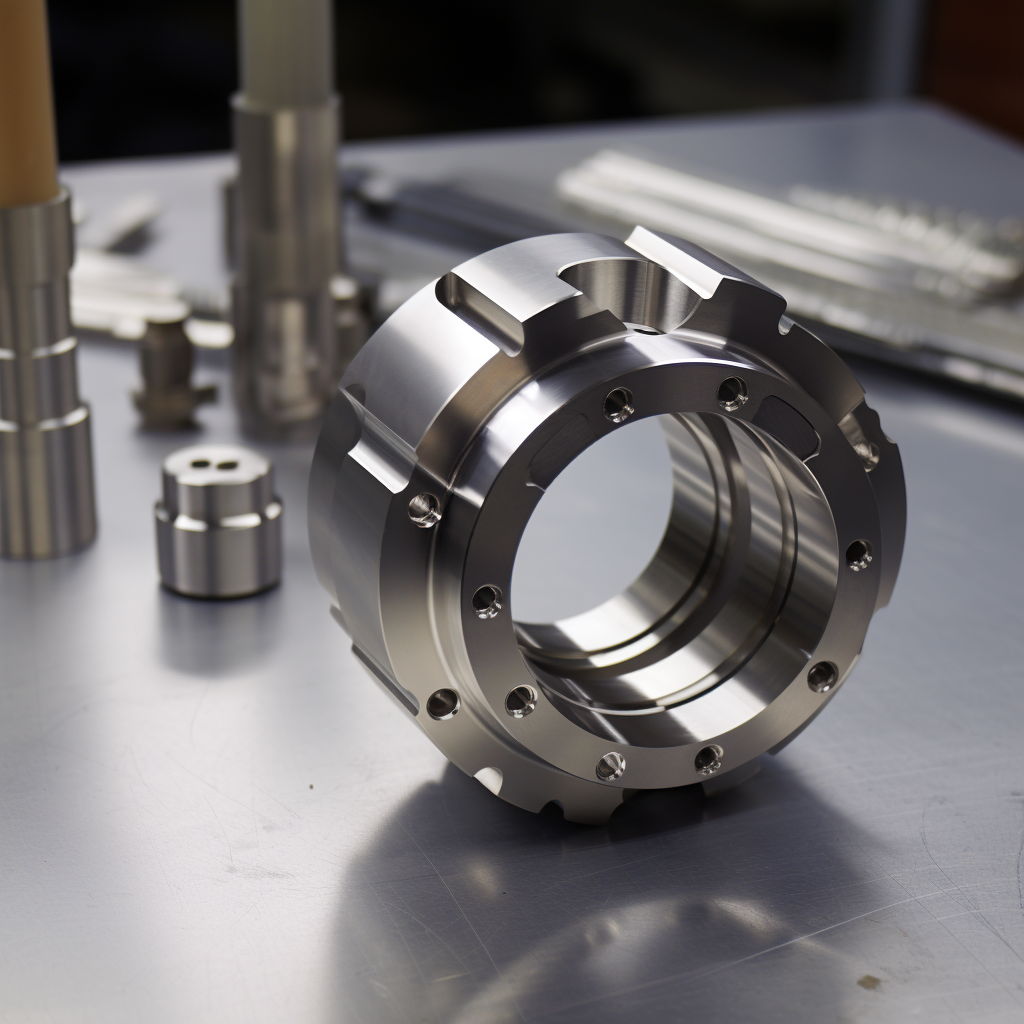

CNC machined sample parts

Precision prototypes and production parts we've delivered for customers worldwide.

Our corporate video

Industries

Delivering precision excellence across critical sectors:

Aerospace

Mission-critical components with full traceability for flight-worthy performance.

Learn more

Oil & Gas

High-precision parts for extreme environments and demanding energy applications.

Learn more

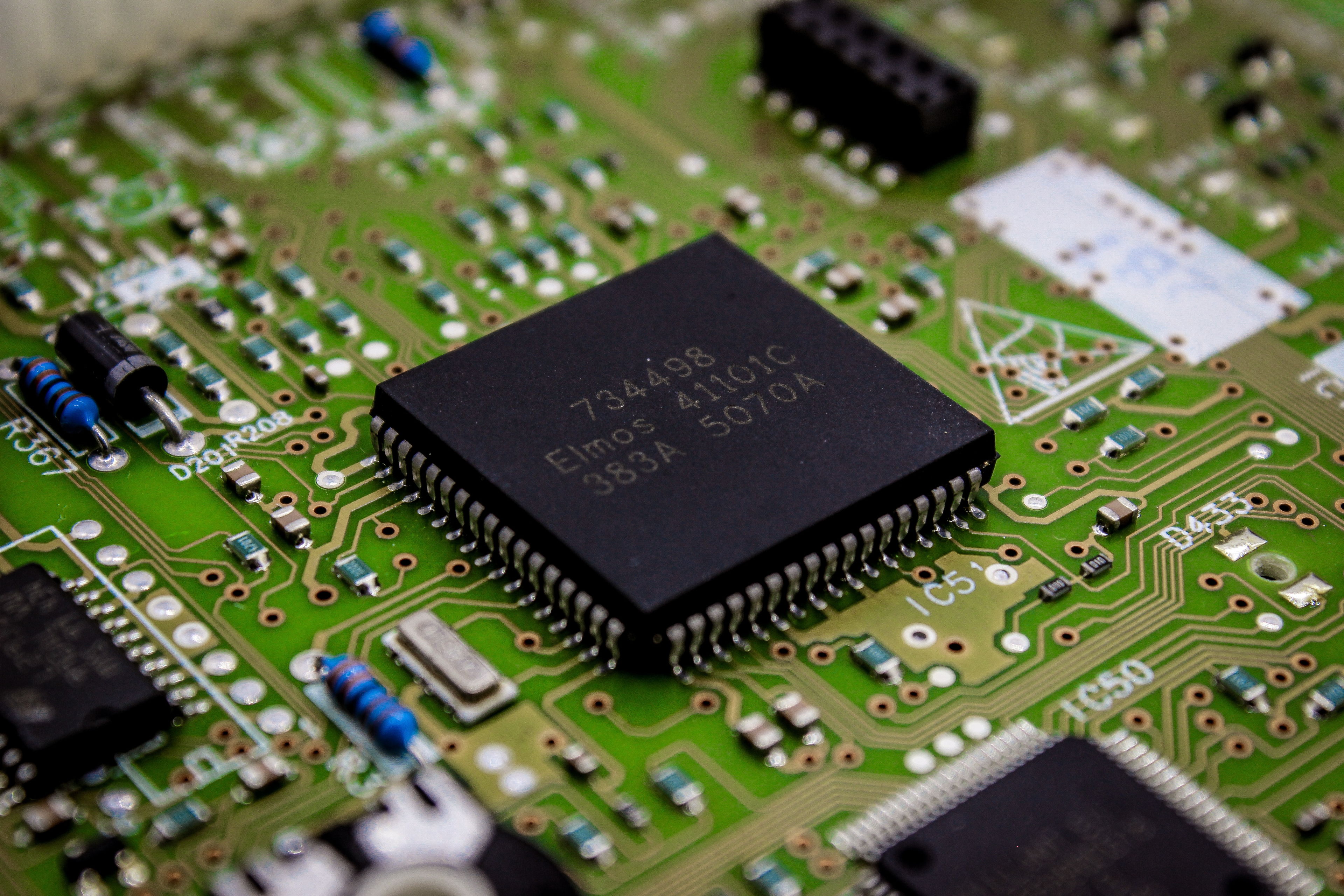

Semiconductor

Ultra-precision components for chip manufacturing equipment.

Learn more

Optics

Precision optical components for superior clarity and performance.

Learn more

Automotive

Performance-driven parts for traditional and electric vehicles.

Learn more

Medical

Precision components manufactured in cleanroom environment for medical device applications.

Learn more

Why choose us for custom CNC machining?

Singapore Advantage

35+ years established in Asia's most trusted manufacturing hub. Political stability, robust IP protection, strategic global access.

Technical Expertise

Proven ability to handle tight tolerances and complex geometries. Every project meets stringent precision engineering standards.

Complete Solutions

Single-source manufacturing eliminates multiple vendors. Streamlined experience from concept to delivery.

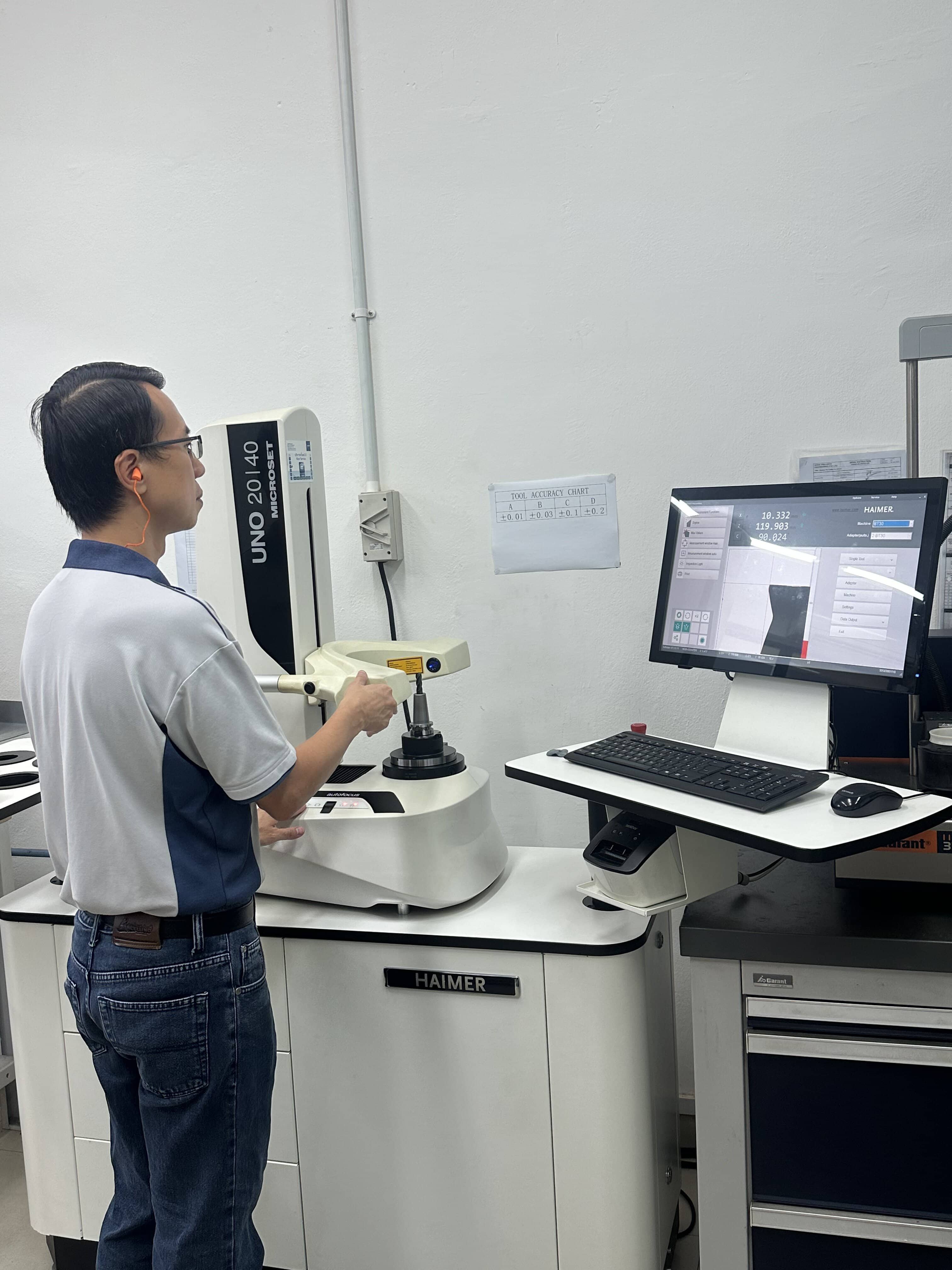

Industry 4.0 Operations

Robotic cells, RFID tracking, automated quality controls. Advanced technology ensures efficiency and zero-defect precision.

Quality Assurance

ISO 9001:2015 certified processes guarantee consistent, reliable excellence in every component.

Gallery of facility & operations

A look at the precision engineering that drives our operations, in Singapore at our 34,000 sqft facility.

From rapid prototyping to production

Whether you’re in the early stages of development or require large-scale production, we’re here to deliver precision and excellence at every stage of your project.

Prototype machining

Turn ideas into reality fast. Precision prototypes for faster design validation.

- Speedy quotes

- Expert DFM feedback

- Excellent quality

- Fast delivery

Low-volume machining

Quality and affordability for small to medium quantities.

- Lower cost

- Production-level quality

- Fast delivery

- Market testing capability

Production machining

High volumes at competitive costs with guaranteed consistent quality.

- DFM optimization

- First Article Inspection (FAI)

- Consistent quality

- Reliable delivery

CNC prototypes and parts made easy

Get 7-day standard lead times on simple parts between 12.7 x 12.7mm (0.5 x 0.5 in.) and 101.6 x 101.6 mm (4 x 4 in.). Send us your requirements to see if we can help.

Our ordering process

Request for quote

Share project details for competitive pricing

Quote and design analysis

Detailed quote with design evaluation

Production

Precision manufacturing with advanced CNC systems

Quality control

Rigorous inspections ensure specifications

Delivery

Reliable shipping worldwide

CNC machining tolerances

Our guide to understand the precision and accuracy we offer in both milling and turning processes. Discover the exacting standards we maintain to ensure the parts meet your specifications.

| CNC Milling | CNC Turning | |

|---|---|---|

| Maximum Part Size | 1600 x 1200 x 600mm 63.0 × 47.2 × 23.6 in. | 650 x 3000mm 25.6 × 118.1 in. |

| Minimum Part Size | 4 × 4 mm 0.1 × 0.1 in. | 2 × 2 mm 0.079 × 0.079 in. |

| Standard Tolerances | Φ 0.050 mm Φ 0.00197 in. | Φ 0.050 mm Φ 0.00197 in. |

| Linear Dimension | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Hole Diameters (Not Reamed) | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Shaft Diameters | +/- 0.025 mm +/- 0.001 in. | +/- 0.025 mm +/- 0.001 in. |

| Edge Condition | *Sharp corners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| We can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of 0.5 mm, depth of 0.1 mm We can use CNC engraving or laser carving to create standard textbased on customers’ requirements. | We can use laser marking to create standard text for CNC turned parts. |

Maximum Part Size

- CNC Milling1600 x 1200 x 600mm

63.0 × 47.2 × 23.6 in. - CNC Turning650 x 3000mm

25.6 × 118.1 in.

- CNC Milling1600 x 1200 x 600mm

Minimum Part Size

- CNC Milling4 × 4 mm

0.1 × 0.1 in. - CNC Turning2 × 2 mm

0.079 × 0.079 in.

- CNC Milling4 × 4 mm

Standard Tolerances

- CNC MillingΦ 0.50 mm

Φ 0.00197 in. - CNC TurningΦ 0.50 mm

Φ 0.00197 in.

- CNC MillingΦ 0.50 mm

Hole Diameters (Not Reamed)

- CNC Milling+/- 0.025 mm

+/- 0.001 in. - CNC Turning+/- 0.025 mm

+/- 0.001 in.

- CNC Milling+/- 0.025 mm

Shaft Diameters

- CNC Milling+/- 0.025 mm

+/- 0.001 in. - CNC Turning+/- 0.025 mm

+/- 0.001 in.

- CNC Milling+/- 0.025 mm

Edge Condition

- *Sharp corners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing.

Threads and Tapped Holes

- CNC MillingDiameter: Φ 1.5-5 mm, depth: 3×diameter

Diameter: Φ 5 mm or more, depth: 4-6×diameter - CNC TurningDiameter: Φ 1.5-5 mm, depth: 3×diameter

Diameter: Φ 5 mm or more, depth: 4-6×diameter - We can produce threads of any specification and size required by our customers.

- CNC MillingDiameter: Φ 1.5-5 mm, depth: 3×diameter

Text

- CNC MillingMinimum width of 0.5 mm, depth of 0.1 mm

We can use CNC engraving or laser carving to create

standard text based on customers’ requirements. - CNC TurningWe can use laser marking to create standard text

for CNC turned parts.

- CNC MillingMinimum width of 0.5 mm, depth of 0.1 mm

CNC machining materials

We accommodate a wide variety of metals and plastics and can source any material. If you don’t find the material you need listed, don’t hesitate to reach out to us. We’re always willing to explore possibilities to ensure your project’s unique requirements are met.

- Aluminium

- Stainless steel

- Mild steel

- Brass

- Copper

- Alloy steel

- Tool steel

- Titanium

- Inconel

- Invar

Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. Can be anodized.

- POM (Delrin/Acetal)

- Nylon

- PPSU

- ABS

- PEEK

- PTFE (Teflon)

- Polycarbonate (PC)

- Polyethylene

- PVC

- PMMA (Acrylic)

- PET

- Polypropylene

- G-10

- FR4

- PEI

POM, also known as Delrin or Acetal, is a high-strength, low-friction engineering plastic known for its excellent dimensional stability and wear resistance. It is often used in precision parts and gears.

Surface finishing

An array of surface finishing options are available from both in-house facility and reliable external vendors.

- As machinedApplicable to:Metals, PlasticsMachining marks:Visible, light surface scratchesCosmetic availability:NoColour:N/ATolerances:Tolerances are not affected

- Smooth machiningApplicable to:Metals, PlasticsMachining marks:Visible, light surface scratchesCosmetic availability:NoColour:N/ATolerances:Tolerances are not affected

- Fine machiningApplicable to:MetalsMachining marks:Slightly visibleCosmetic availability:NoColour:N/ATolerances:Tolerances are not affected

- PolishingApplicable to:MetalsMachining marks:Removed on primary surfacesCosmetic availability:Always cosmeticColour:N/ATolerances:Met after polishing

- Bead blastingApplicable to:MetalsMachining marks:Removed for non-cosmetic, removed on primary surfaces for cosmeticCosmetic availability:On requestColour:N/ATolerances:Not affected except for specific features*

- BrushingApplicable to:MetalsMachining marks:Reduced for non-cosmetic, removed on primary surfaces for cosmeticCosmetic availability:On requestColour:N/ATolerances:Met after brushing

- Anodizing Type IIApplicable to:AluminumMachining marks:Reduced for non-cosmetic, removed on primary surfaces for cosmeticCosmetic availability:On requestColour:Black, Clear, Red, Blue, Gold, OrangeTolerances:Met after anodizing

- Anodizing Type IIIApplicable to:AluminumMachining marks:Visible under anodizingCosmetic availability:NoColour:Black, NaturalTolerances:Met after anodizing

- Black oxideApplicable to:Copper, Stainless steel, Alloy steel, Tool steel, Mild steelMachining marks:VisibleCosmetic availability:NoColour:BlackTolerances:Met after coating

- Chromate conversion coatingApplicable to:AluminumMachining marks:VisibleCosmetic availability:NoColour:ClearTolerances:Met after coating

- Electroless nickel platingApplicable to:Mild steel, Aluminum, Stainless steelMachining marks:Reduced but visibleCosmetic availability:NoColour:Metallic (semi-bright)Tolerances:Met after electroless nickel plating

- Powder coatingApplicable to:MetalsMachining marks:RemovedCosmetic availability:NoColour:Black, White, RAL/PantoneTolerances:Met before powder coating

- Brushed + electropolishingApplicable to:Stainless steelMachining marks:Removed on Primary surfacesCosmetic availability:Always cosmeticColour:N/ATolerances:Met after electropolishing

| Name | Applicable to | Machining marks | Cosmetic availability | Color | Tolerances |

|---|---|---|---|---|---|

| As machined | Metals, Plastics | Visible, light surface scratches | No | N/A | Tolerances are not affected |

| Smooth machining | Metals, Plastics | Visible, light surface scratches | No | N/A | Tolerances are not affected |

| Fine machining | Metals | Slightly visible | No | N/A | Tolerances are not affected |

| Polishing | Metals | Removed on primary surfaces | Always cosmetic | N/A | Met after polishing |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic | On request | N/A | Not affected except for specific features* |

| Brushing | Metals | Reduced for non-cosmetic, removed on primary surfaces for cosmetic | On request | N/A | Met after brushing |

| Anodizing Type II | Aluminum | Reduced for non-cosmetic, removed on primary surfaces for cosmetic | On request | Black, Clear, Red, Blue, Gold, Orange | Met after anodizing |

| Anodizing Type III | Aluminum | Visible under anodizing | No | Black, Natural | Met after anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible | No | Black | Met after coating |

| Chromate conversion coating | Aluminum | Visible | No | Clear | Met after coating |

| Electroless nickel plating | Mild steel, Aluminum, Stainless steel | Reduced but visible | No | Metallic (semi-bright) | Met after electroless nickel plating |

| Powder coating | Metals | Removed | No | Black, White, RAL/Pantone | Met before powder coating |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces | Always cosmetic | N/A | Met after electropolishing |